Latin America. Pump specialist Armstrong Fluid Technology introduces new product solutions designed to help building managers achieve significant energy and cost savings. Here's what's new.

High efficiency circulators with ECM motor technology

Two new high-efficiency COMPASS R models with ECM motor technology for energy savings of up to 80%. With an air-cooled ECM motor and advanced Design Envelope variable speed technology, the new COMPASS R20-35 and R40-45 circulators can replace many competing models with screw-to-screw connection capability. The new COMPASS R models cover a wide range of features and are energy-efficient upgrades for two- and three-piece and wet-rotor circulators.

Other features of the new circulators (cover photo):

• Posi-Start technology for smooth start and automatic unlocking

• Multiple control options, including a patented "Auto" mode

• Optimized hydraulics with dry rotor design

• Easy selection of the right flow and pressure to meet system demand

• Easy-to-read control panel

• Electrical terminal box designed for quick installation

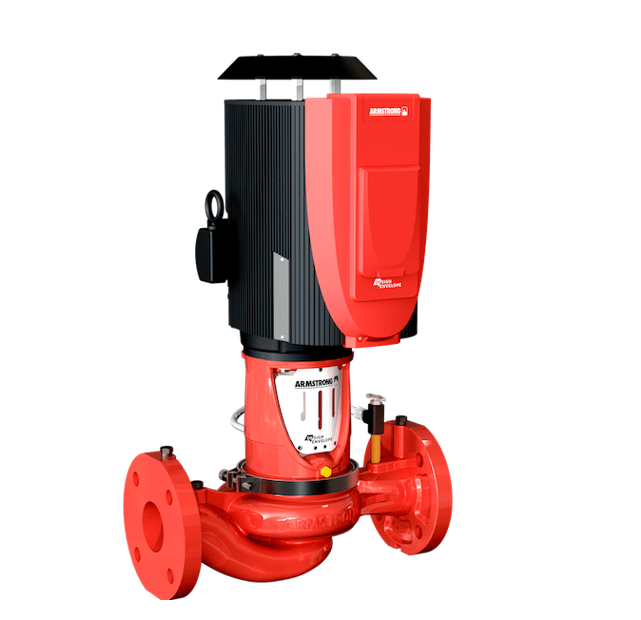

New line of outdoor pumps with permanent magnet motors up to 10 hp

Armstrong also announced that Design Envelope Permanent Magnet motor pumps are now available with NEMA 4X/IP66 rating for outdoor installation.

With advanced performance mapping technology and load limitation logic, the new pumps reduce energy consumption by up to 30% compared to pumps supplied with a loose variable speed drive. Together with a new pump hydraulic system that is more efficient, the new pumps from 1 to 10 hp can save an additional 20% compared to competing integrated products with induction motors.

Other features of the new Design Envelope outdoor pumps:

Other features of the new Design Envelope outdoor pumps:

• Cover to protect the touchscreen user interface from dirt and sunlight

• Shield to protect the motor fan against ice stiffness

• Factory-tested and TL-approved NEMA 4X rated controls

• Available Parallel Sensorless control provides additional energy savings by providing the best efficiency

• Available Pump Manager service provides pump performance tracking along with alerts, alarms and data storage

"The conventional approach for roof and outdoor pumps is to install the variable frequency drives on a central control panel with outdoor rating, separate from the pumps. This adds unnecessary costs and requires more space," said Zeljko Terzic, Director of Global Pump Offering. "Our new Design Envelope pumps feature integrated controls to take up less space and substantially reduce installation costs."

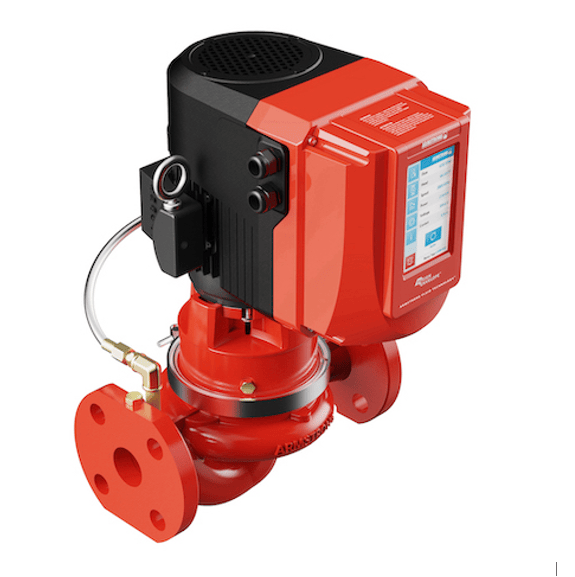

Single-phase pumps for light installations As additional developments, Armstrong has announced a new version of its Design Envelope pump to service light duty installations in which the available energy is single-phase.

As additional developments, Armstrong has announced a new version of its Design Envelope pump to service light duty installations in which the available energy is single-phase.

The new Design Envelope pumps are now available for use with single-phase (200-230 V) power from 1/3 to 2 hp and are built to a design standard inherited from commercial pumps.

As with all Design Envelope pumps, the technology is built around an intelligent, demand-driven control solution that:

• Models the behavior of equipment and systems

• Monitors actual system conditions

• Dynamically adjusts equipment operation to adapt to system demand

• It is designed to provide the highest energy efficiency and the lowest installation and operating costs.

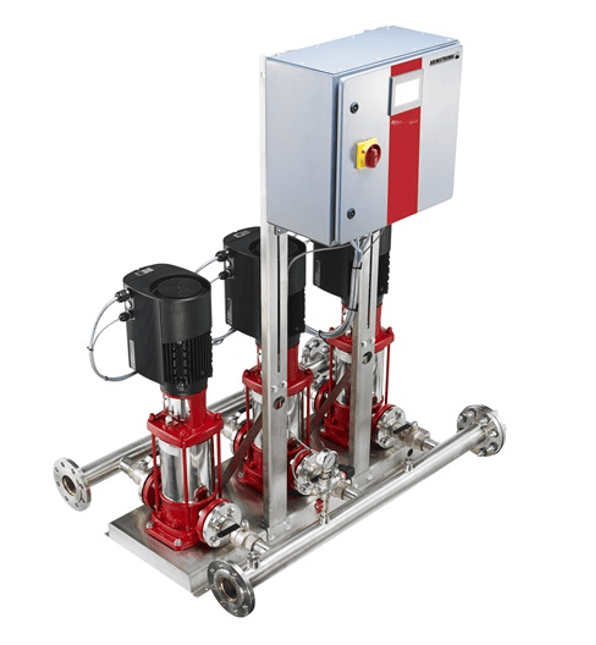

Energy-efficient booster packages with permanent magnet motors

Finally, Armstrong has presented the most efficient power-up in its history. Its latest generation of DE6800 power-up packages is now available with Design Envelope permanent magnet motors (for pump capacities of 1-10 hp).

Design Envelope Permanent Magnet Motors provide significant added value compared to the current industry standard for variable speed induction motors.

Design Envelope Permanent Magnet Motors provide significant added value compared to the current industry standard for variable speed induction motors.

• Reduced running costs thanks to 15% more energy efficiency

• Increased reliability translates into reduced maintenance requirements, fewer mechanical breakdowns, better uptime percentages, longer service life and lower operating costs over the entire service life

• Lower weight makes it easy to handle and install on site

• Quieter operation

• Wide range of operating speeds

• Flexibility of design and installation through safety factors in the operating capacity

For more information on any of these and many other energy efficiency solutions visit www.armstrongfluidtechnology.com

Leave your comment